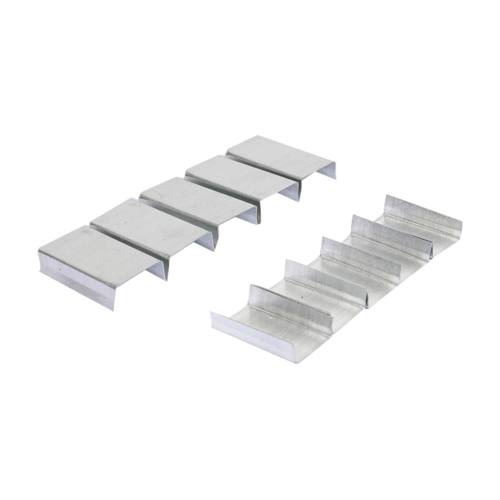

What are

strapping seals?

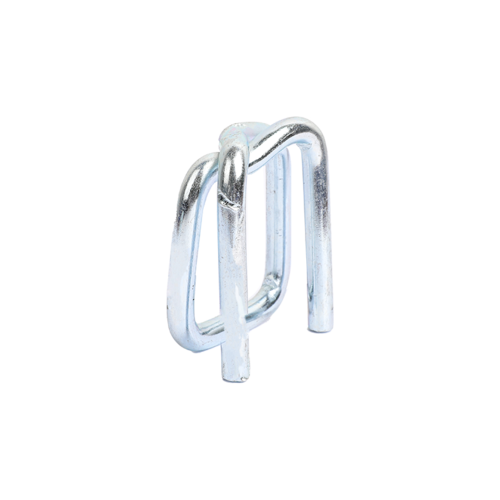

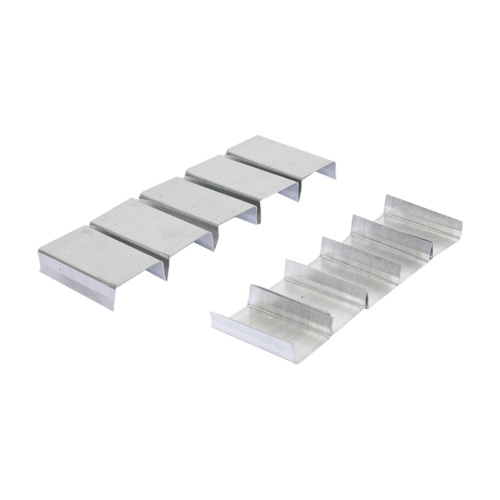

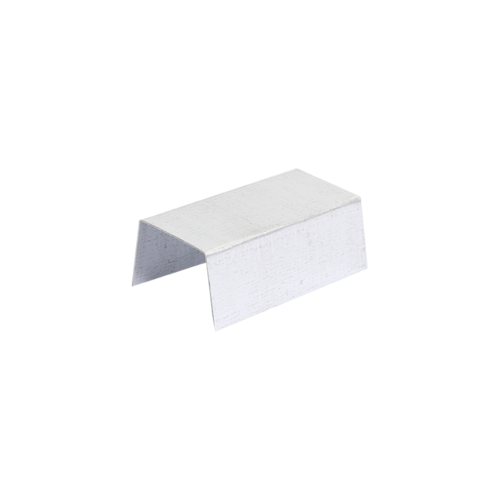

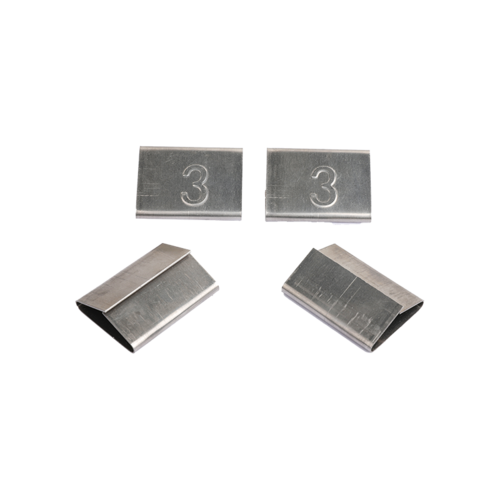

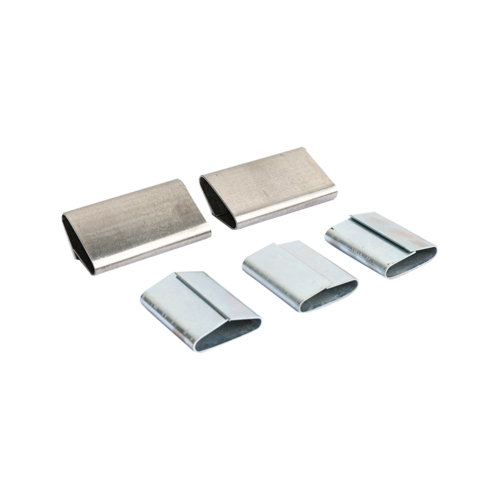

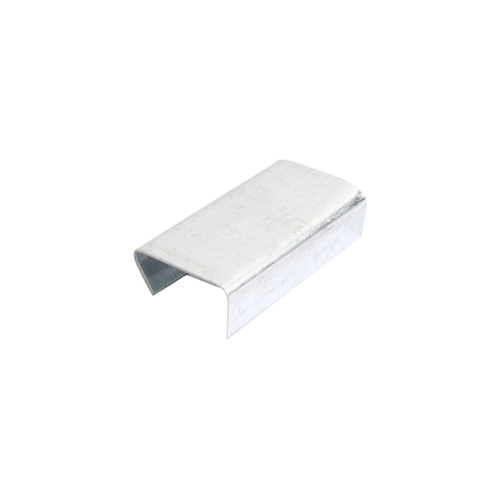

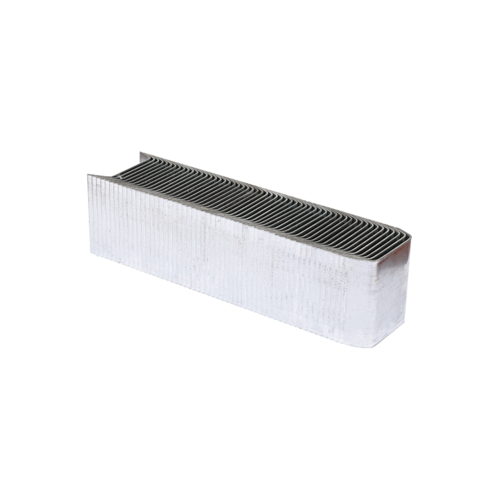

Lashing seals are small clip-like devices used to secure the ends of a metal strap after it has been tightened around a load. They are commonly used in packaging, shipping and storage applications to secure loads such as pallets, crates and boxes.

Strapping seals are designed to crimp or lock into place on the end of a metal strap, creating a secure and tamper-resistant connection. Seals help prevent straps from loosening or unraveling, keeping loads safe during transport or storage.

Different types of lashing seals are available including steel seals, plastic seals and combination seals. The type of seal used depends on the specific application and the properties of the metal strip used.

When using strapping seals, it is important to select the proper type of seal for the job and to crimp or lock the seal properly in place to ensure a secure connection. It is also important to check the seals and straps regularly to ensure the load remains secure, and to replace any damaged or worn seals if necessary.

Overall, a lashing seal is a simple but essential component used to secure cargo for transport or storage. They help provide a secure, tamper-resistant connection, ensuring loads remain safe and protected during handling, transport and storage.

How are

strapping seals stored?

1. Temperature

Generally speaking, the storage temperature of

strapping seals should not exceed 50°C (120°F), and should be kept within 30°C if possible. Cold temperatures are not permanently harmful to most rubber items, as long as they are handled with care and do not hang or put them under pressure. When removed from cold environments, the material should be warmed to approximately 30°C (70°F) prior to use.

2. Humidity

In a draftless environment, the optimum humidity is about 65%. In the period of high humidity in spring and summer, the inventory should be reasonably controlled, and it is not suitable to store a large number of inventory products.

3. Light (sunlight, strong artificial light)

It is important to avoid direct sunlight and artificial lights with high UV content. Unless stored in opaque packaging, it is recommended to cover windows with red or orange glass or coating.

4. Oxygen and ozone

Stretchy items should avoid air circulation as much as possible. Because ozone is particularly harmful to rubber, storage warehouses should avoid using equipment that may cause electric sparks or discharges. Vulcanized rubber products should be stored in packaging, sealed containers or other suitable means.

5. Deformation

Rubber items should be stored in a relaxed, flat state, not under tension or compression. Avoid hanging or crushing to avoid deformation.

6. Contact with liquid and semi-solid substances

All sealing materials and components should avoid contact with liquid and semi-solid materials (especially solvents such as oil or grease).

7. Contact with metal

Metals or copper alloys such as manganese, iron, and copper may have a deleterious effect on the rubber and can be separated by a cardboard or cellophane spacer.

8. Contact with non-metal

This condition should avoid contact with other rubber or creosote. The packaging medium should also be selected reasonably. For example, the packaging material of PE shrink film containing extender is not suitable for polyurethane

strapping seals. The extender contained in PE packaging material will penetrate into polyurethane and affect the performance of polyurethane.

9. Inventory turnover

Inventory management should be done in combination with different sealing materials, and the same type should be stored in the same period as much as possible. Elastomers should be stored as short-term as possible and strictly rotated.

10. Clean

Cleaning agents that are harmful to sealing materials are usually organic solvents such as trichlorethylene, carbon tetrachloride, and petroleum. Soap, water, and methylated spirits are minimal hazards, and all parts should be stored dry at room temperature before use.

English

English

中文简体

中文简体