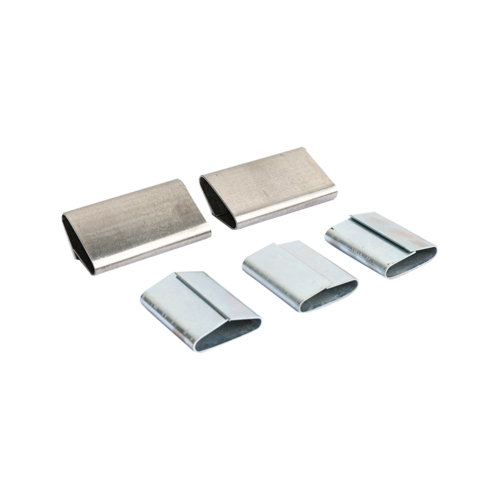

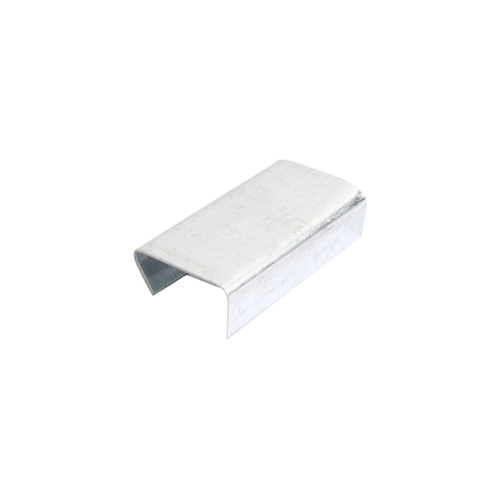

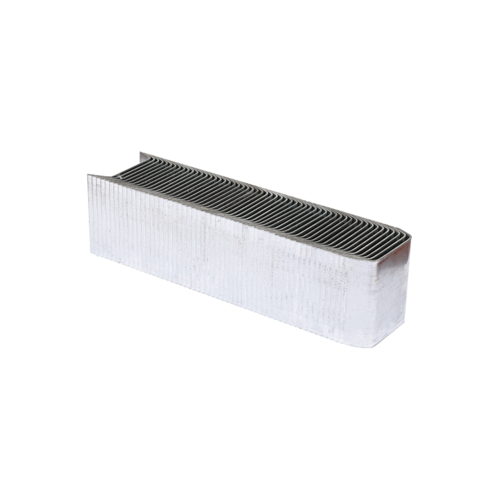

The greater the tension, the better the steel strapping seal. Although increasing the tension appropriately can improve the sealing performance and the firmness of strapping, excessive tension may actually bring a series of problems. Specifically, potential issues with excessive pulling force include:

1. Plastic deformation of materials

Steel strips or wires may undergo plastic deformation when subjected to excessive tension, resulting in changes in the shape or damage of the sealing components. Excessive tension can cause the steel strip to stretch excessively, which may lead to surface cracks, deformation, or even fracture, affecting the sealing effect.

2. Excessive compression of sealing materials

Excessive tension may cause the seal to be compressed excessively, resulting in the loss of its original elasticity and affecting its sealing performance. When the seal is subjected to excessive tension, it may reduce its pressure on the contact surface, resulting in uneven sealing and increasing the risk of leakage.

3. Increase wear and tear

Excessive pulling force may also increase the friction between the seal and the connecting surface, thereby exacerbating wear and shortening the service life of the seal. This is particularly significant in long-term high-pressure environments.

4. Strength limit of steel strip or wire

Every type of steel has its ultimate tensile limit, and exceeding this limit may cause the steel strip or wire itself to fracture or break, resulting in seal failure. Therefore, the tension of the steel strapping seal must be controlled within the safe tensile range of the steel.

5. Uneven pressure distribution

If the tension is too high, the pressure distribution in the strapping area may be uneven, and some areas may be subjected to excessive compression, while other areas may be stretched excessively, resulting in unsatisfactory sealing effect. This uneven pulling force can reduce the sealing performance of the seal and may even lead to sealing failure.

English

English

中文简体

中文简体