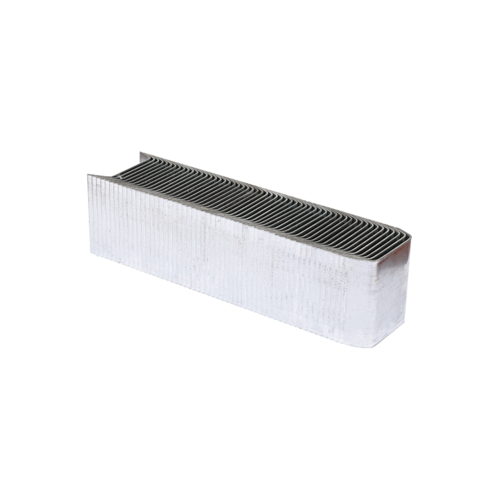

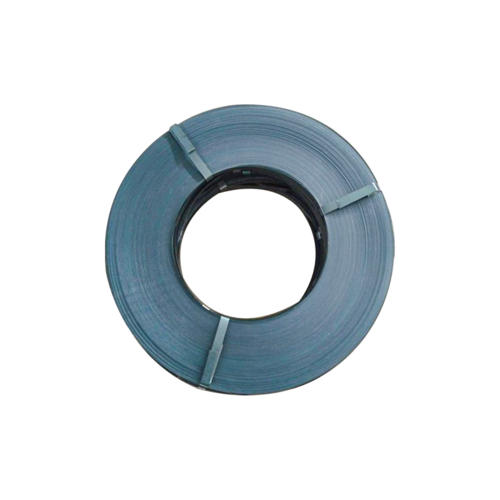

The suitability of steel strapping buckles for long-term outdoor exposure mainly depends on their material, surface treatment process, and usage environment. The following is a point by point introduction:

1. Material weather resistance: If the steel strapping buckle is made of stainless steel or galvanized steel, it has strong corrosion resistance and can adapt well to long-term outdoor exposure environments such as rain, humidity, UV radiation, etc. On the contrary, if the buckle made of ordinary carbon steel material is not treated with anti-corrosion, it is easy to rust after long-term outdoor use, thereby reducing its strength and service life.

2. Surface treatment process: Steel strapping buckles with galvanized, painted or electrophoretic surface treatment have strong oxidation and corrosion resistance, making them more suitable for long-term outdoor use. If not treated with any protective measures, steel buckles will oxidize and corrode due to moisture and pollutants in the environment, affecting their structural strength and safety performance.

Environmental adaptability: Under extreme weather conditions such as high humidity, strong ultraviolet radiation, acid rain, and salty coastal air, ordinary steel buckles are prone to corrosion. Therefore, 304 or 316 stainless steel buckles should be preferred to ensure their long-term stability and reliability.

Service life and maintenance: Even if steel strapping buckles with strong corrosion resistance are selected, it is recommended to regularly check the firmness and surface condition of the buckles after long-term outdoor exposure, and replace fasteners that have already corroded or fatigued in a timely manner to prevent fixing failure due to material degradation.

English

English

中文简体

中文简体