Shaoxing Dingli New Material Technology Co., Ltd. stands as a distinguished professional manufacturer of Steel Strapping in China, boasting an impressive 13-year tenure. Situated in Shaoxing, Zhejiang, our strategic location places us in close proximity to the bustling ports of Ningbo and Shanghai.

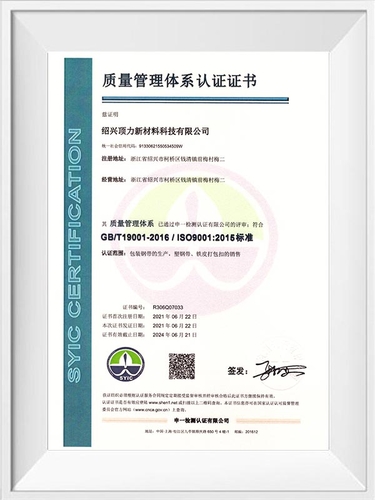

Dingli New Materials is recognized as a national high-tech enterprise. Our company has successfully obtained rigorous and authoritative ISO9001、ISO14001、ISO45001 and SGS certifications. Furthermore, our independently developed winding and leveling device has secured several national patents, underlining our commitment to innovation and excellence.

In collaboration with Zhejiang University, a prominent institution in China, our company has established an electromagnetic heating test facility. This advanced facility plays a pivotal role in offering scientific and technical backing for the multifaceted and meticulous evolution of our company's product portfolio.

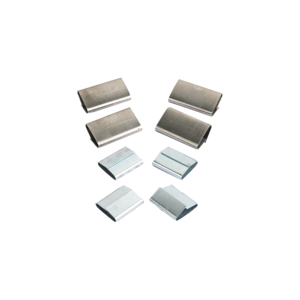

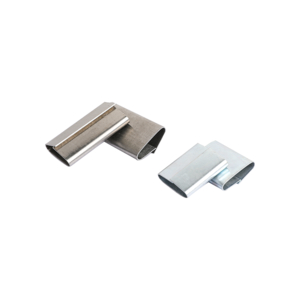

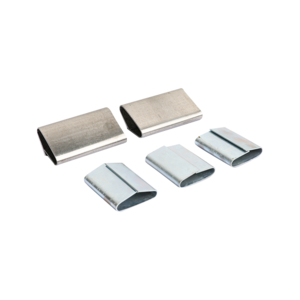

| Origin: | Shaoxing Qianqing | Whether to import: | No | Custom processing: | Yes |

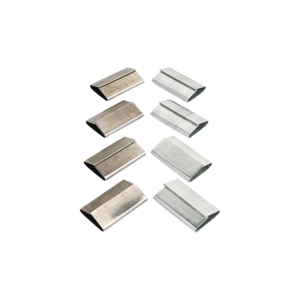

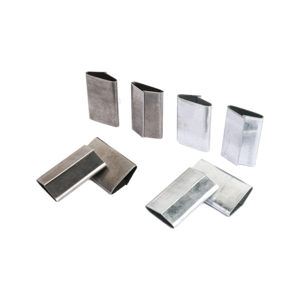

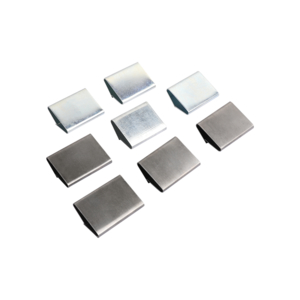

| Article number: | 1117C01 | Scope of application: | Product packaging | Material: | Q195 Q235 Q345 |

| Brand: | Dingli | Whether for cross-border export: | Supply | Specification: | 32,19,16 |

English

English

中文简体

中文简体