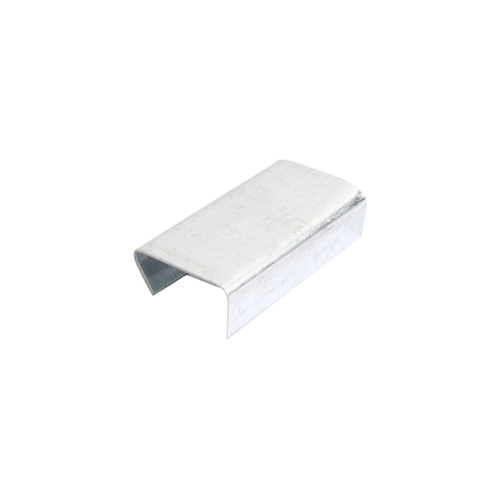

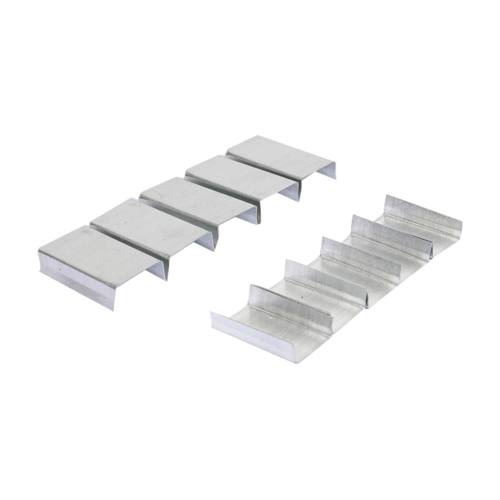

If cylindrical goods need to be tied, it is usually recommended to use specially designed steel strapping seals to ensure a more secure, safe, and efficient tying process. Below, we will introduce the reasons and considerations from multiple perspectives:

1. Adapt to the shape of cylindrical surfaces

Ordinary flat steel strips are prone to slipping or uneven adhesion on the surface of cylindrical bodies, resulting in uneven local stress.

Special steel strapping seals usually have a certain degree of flexibility or specific bending structure design, which can better fit the cylindrical surface, ensuring uniform force distribution and reliable fastening.

2. Prevent sliding or detachment

Cylindrical goods are prone to rolling or rotating during transportation, and using mismatched strapping seals may cause the straps to loosen or slip.

Special sealing components may have anti slip structures (such as anti slip teeth, textures) or can be used in conjunction with anti roll grooves to enhance grip and prevent displacement.

3. Optimize the bundling angle and locking method

Cylinders do not have obvious edges like square objects, and rely more on surrounding tension and reliable locking when bundling.

Special steel strapping seals are often equipped with specific buckles, locks, or closure devices, suitable for circular structures, to enhance sealing stability.

4. Improve operational efficiency

Steel strip systems designed for cylindrical objects are usually easy to locate and install, and can be quickly tightened and fixed with tools, reducing manual adjustments and improving bundling efficiency.

Some specialized tools, such as tensioners or fastening machines, are also used in conjunction with these seals for greater convenience.

5. Prevent damage to goods

If ordinary steel strapping is not attached to the surface of the cylinder, it is easy to form pressure concentration points, which may damage the surface or edges of the cylinder.

Special seals are usually equipped with corner protectors, protective sleeves, or widened areas to effectively disperse tension and avoid damaging the surface of goods, especially suitable for fragile shell items such as paper tubes, plastic barrels, and steel cylinders.

English

English

中文简体

中文简体