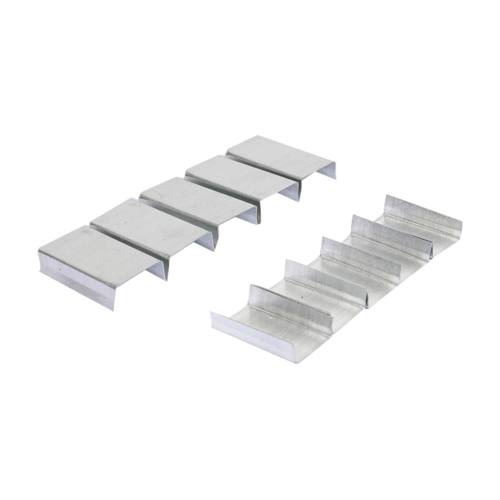

The size of the steel strapping seal must be adapted to the size of the goods, otherwise it will affect the strapping effect and sealing performance. Below is a detailed explanation of the reasons:

1. Ensure sufficient coverage and strapping range

The seal size is too small to cover the key strapping parts of the goods, resulting in weak strapping or missing strapping.

Appropriate sized seals can fully wrap the goods, ensuring that the strapping area is adequately secured and sealed.

2. Ensure even distribution of tension

A properly sized seal can evenly distribute tension, prevent excessive or insufficient local stress, and reduce the risk of cargo damage and seal failure.

Mismatch in size can easily cause concentrated or uneven tension, reducing the firmness of strapping.

3. Avoid material waste and operational difficulties

The size of the seal is too large, which wastes materials and increases costs. At the same time, it may cause knots or excess parts during operation, affecting efficiency.

The appropriate size facilitates quick operation and installation, improving work efficiency.

4. Adapt to the shape and packaging form of the goods

Goods of different shapes (rectangular, cylindrical, irregular) require seals of different sizes and shapes to achieve the best strapping effect.

Adapting to the size helps protect the edges and corners of the goods, avoiding damage.

5. Meet transportation and storage safety requirements

Seals that adapt to the size of the goods can ensure stability during transportation, avoiding damage or loss of goods caused by loose or broken seals.

Seals that meet the required size can also withstand external forces such as transportation vibrations and impacts, enhancing safety.

6. Meet the requirements of standards and specifications

Many industries and transportation standards have clear regulations on the size of strapping seals, and seals that meet the standards must be selected based on the size of the goods.

Ensure legality and compliance while avoiding potential security risks.

English

English

中文简体

中文简体