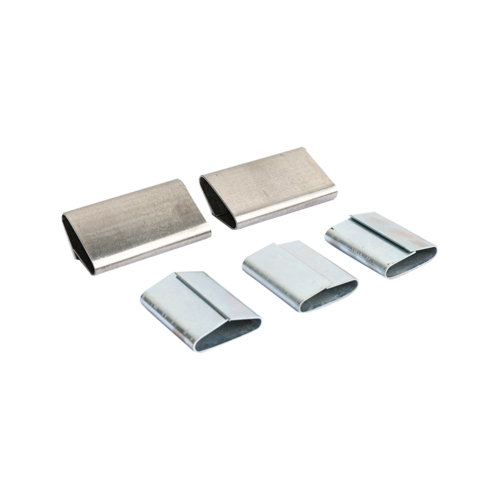

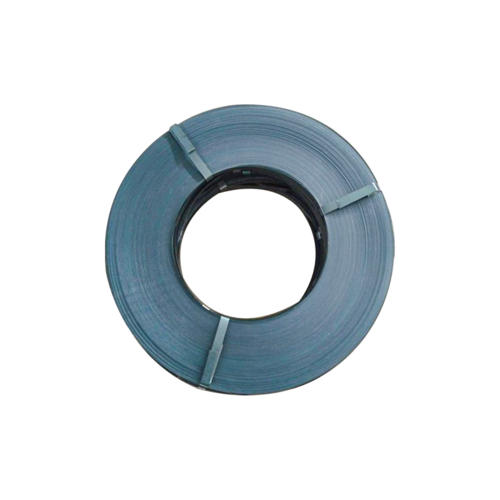

When choosing steel strapping buckles, the safety redundancy factor is a key factor that must be considered. Redundancy factor refers to the safety margin set to cope with possible overload or unexpected situations, ensuring that the bundling system can still operate normally without failure under extreme conditions. Redundancy factor is particularly important when bundling heavy items, equipment, or during transportation, especially when carrying heavy items or in harsh environments.

Specifically, the selection of steel strapping buckles should take into account the load-bearing capacity of the steel strip, the weight of the tied object, and possible additional impact forces. For example, sudden braking, vibration, or other external factors that may occur during transportation may cause the load on the buckle and steel strip to exceed the originally designed safety range. If there is not enough safety redundancy, the steel strapping system may not be able to provide sufficient fixing force under extreme conditions, resulting in loose or damaged items, and even causing safety accidents.

Therefore, when choosing steel strapping buckles, it is necessary to comprehensively consider the specific conditions of the usage environment and the load-bearing object. Normally, the appropriate model and specifications can be selected based on the standard safety factor to ensure that the steel strapping buckle can withstand unexpected loads or additional pressure, avoiding a single maximum load calculation. Increasing the safety redundancy factor can effectively improve the reliability of the system, especially in the face of unforeseeable situations, ensuring the safety and stability of the fixed system.

English

English

中文简体

中文简体