Introduction to the use of

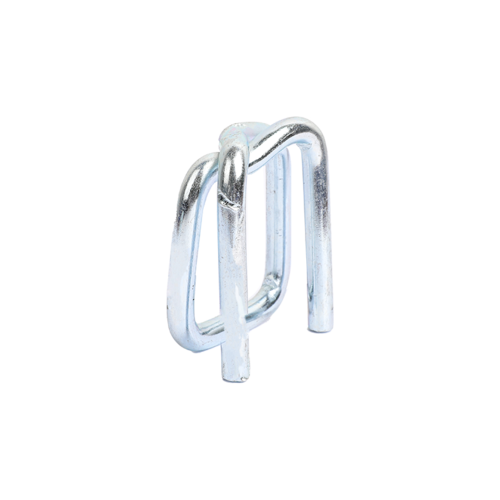

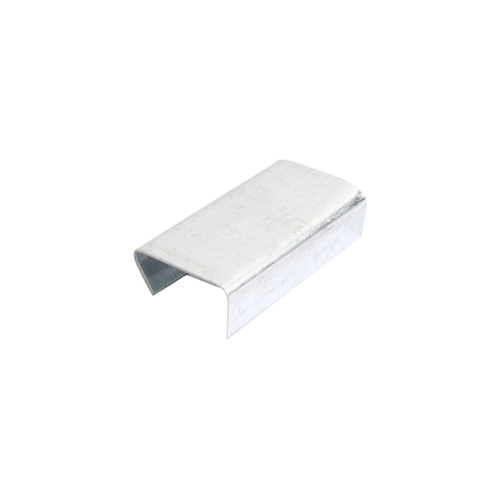

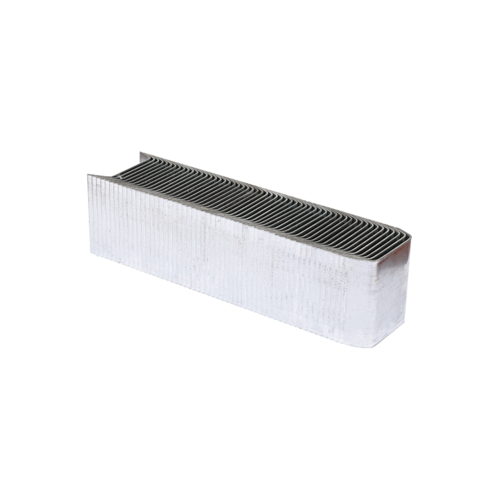

packing belts1. Bend the left end of the packing belt, insert the packing belt buckle, then fold the left fixed rod into the packing belt and tighten it.

2. Hold the packing tape with your right hand and bypass the package, bend the right end of the packing tape into the packing buckle, and fold the left fixing rod into the packing tape.

3. Fix the packing belt buckle with your left hand, press the right end of the packing belt with your right hand, and tighten the packing belt buckle.

4. Finally, cut the strap with scissors. Or use with a baler.

The role of

packing belts in carton packaging

Carton

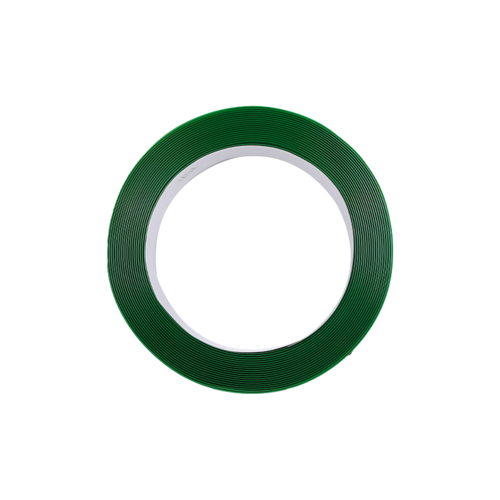

packing belts have good elastic recovery, high strength, good water resistance, strong chemical resistance, light weight and softness, which can be tied by hand or by machine. Easy to use and low cost, it can be made into red, white, blue, yellow, green and other colors, and goods of different grades are bundled according to colors, which is convenient for distinguishing the grades of goods and improving delivery efficiency. In addition to being used for sealing and bundling of corrugated boxes, it can also be used for bundling materials, fruits, etc.

The tensile strength of polyester and nylon strapping is good, while the cost of polyethylene and polypropylene strapping is low, and the resilience of polypropylene is good, and strapping straps of different materials can be selected according to needs.

According to the method of use, plastic strapping can be divided into two types: machine straps (J type) and manual straps (S type).

Can

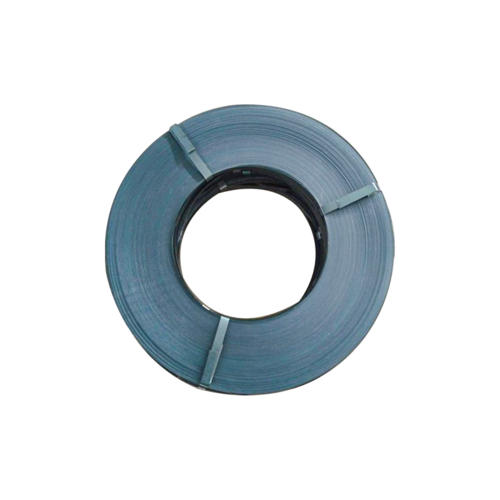

metal strapping be used for cable binding?

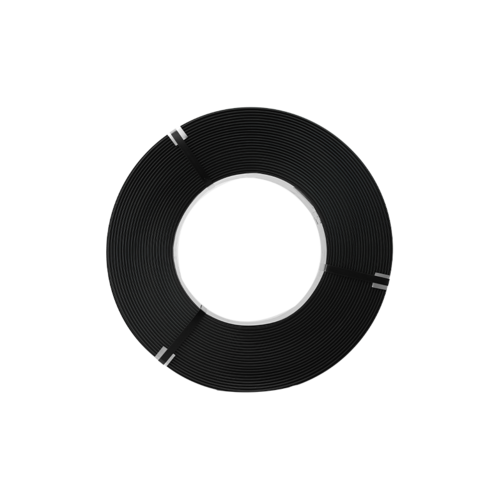

Yes, metal strapping is available for cable bundling. Metal strapping is a strong, durable material that is often used to secure heavy loads or tie items together. When used in cable bundling, metal ties can provide a safe and secure way to organize and protect cables and wires.

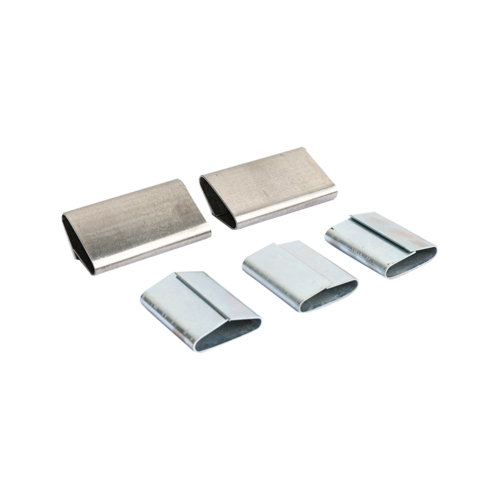

There are different types of metal strapping available including steel, stainless steel and aluminum. Each type of metal strapping has its own unique characteristics, including strength, durability, and corrosion resistance.

When bundling cables with metal straps, it is important to choose the proper size and width to ensure a secure fit around the cables. The metal strap should be tightened around the cable using a strapping tool such as a tensioner or crimper to ensure a tight and secure fit.

It is also important to consider the environment in which the

metal strapping will be used, as certain types of metal strapping may be better suited for certain conditions, such as harsh outdoor environments or areas of high humidity.

In general, metal strapping is a strong, durable and versatile material that can be used in a variety of cable bundling and organizing applications. With proper selection and installation,

metal strapping can provide a reliable and long-lasting solution for securing and protecting cables and wires.

English

English

中文简体

中文简体