Classification and use of

steel strappingSteel strapping is a steel with large output, wide application and many varieties. According to the processing method, it is divided into hot-rolled steel strapping and cold-rolled steel strapping; according to the thickness, it is divided into thin steel strapping (thickness not greater than 4mm) and thick steel strapping (thickness greater than 4mm); according to width, it is divided into wide

steel strapping (width greater than 600mm) And narrow steel strapping (width not greater than 600mm); narrow steel strapping is divided into direct rolling narrow steel strapping and narrow steel strapping slitting by wide steel strapping; according to the surface state, it can be divided into original rolling surface and plated (coated) layer surface Steel strapping; According to the purpose, it is divided into general and special (such as hull, bridge, oil drum, welded pipe, packaging, self-generated vehicle, etc.) steel strapping.

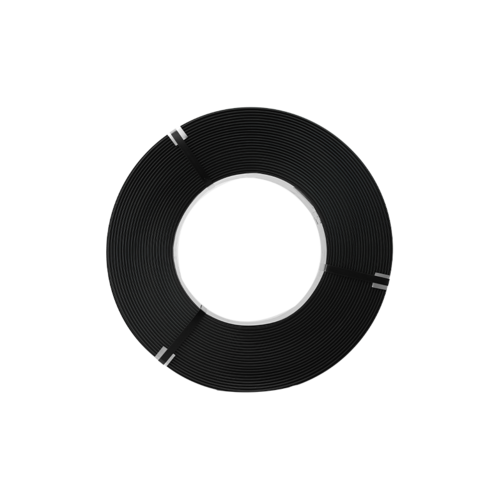

Hardness grade of

steel strappingThe hardness of steel strapping is usually measured according to its Rockwell hardness value, which is expressed as a number followed by the letters "HRC". The Rockwell hardness test is a standard hardness measurement widely used in the metals industry to determine the hardness of steel and other metals.

The hardness of steel strapping can vary depending on the specific type of steel used and the manufacturing process. Commonly used

steel strapping steels have a Rockwell hardness value between 40 and 65 HRC. For example, cold-rolled steel strapping may have a hardness value of around 50 HRC, while heat-treated and tempered steel strapping may have a hardness value of 60 HRC or higher.

It is important to note that the stiffness of the steel strapping is only one of the factors to consider when selecting a

steel strapping for a particular application. Other factors, such as tensile strength, yield strength, ductility, and corrosion resistance, may also be important, depending on the application.

English

English

中文简体

中文简体