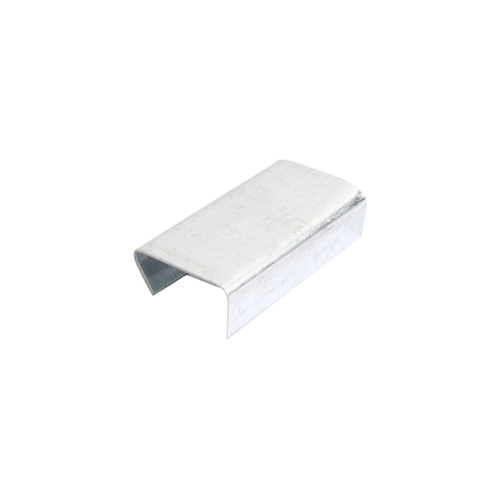

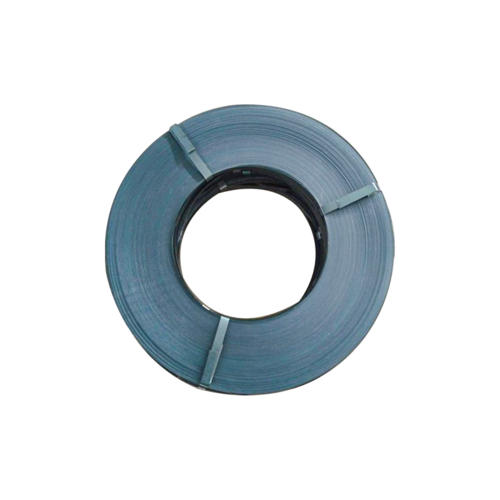

Steel strapping seals can be used to strap sheet metal, but it depends on the situation and requires attention to detail. Explain the following points clearly:

Bundling flatbed stack - can be used, but with limitations:

Bundle and secure a stack of flat steel or aluminum plates (such as 10 or 20 per stack) for easy lifting, loading, or storage. At this point, it is common practice to tie with steel straps and buttons (seals). After tightening the steel strip, it can hold the entire stack of boards to prevent them from sliding and scattering. However, it should be noted that the edges of the board should be padded with cardboard or specialized corner protectors (L-shaped cardboard/plastic corners), otherwise the sharp edges of the steel plate will cut the steel strip in minutes. And the force of tightening the steel strip should be well controlled. If it is too loose, it cannot be tied tightly, and if it is too tight, it may deform the thin plate.

Bundling plate (steel coil/aluminum coil) - commonly used, but requires professional operation:

The standard practice for tying and fixing the outer ring of large steel or aluminum coils produced by steel mills is to use this type of steel strip with buttons. The steel strip is wrapped around the coil one or several times, tightened with pneumatic tools, and the button is pressed and locked to prevent the coil from "loosening" (scattering) during transportation, which can crush people when rolled. However, the surface of the coil is often coated with oil to prevent rust, and the steel strip is prone to slipping, so the position and number of bundles are carefully considered. Usually, several bundles need to be tied horizontally, and then a "waistband" needs to be tied vertically to be secure. Ordinary workers cannot do it, experienced people need to use professional tools.

Bundling a single sheet - not suitable, easy to damage the board:

If it is a large thin metal plate used for bundling single sheets (such as stainless steel plates or color steel plates for decoration), do not use steel straps if you want to fix it securely for easy handling or installation. The force exerted on the steel strip is too strong, and the edges of the thin plate are easily dented (curled), even causing the entire plate to be bent. Moreover, the steel belt buckle protrudes, making it easy to scrape other boards or equipment during lifting. This type of work is usually carried by nylon straps or soft ropes for lifting, which is more reliable and does not damage the board.

Alternative lifting equipment - absolutely not!

Steel strapping is used to secure and prevent sheet metal from falling apart, and should not be used as a lifting tool to hang directly from a hook! The steel strip and buckle cannot withstand the impact force generated by the swinging of the board during lifting, and may break at any time, causing the board to fall, which is very dangerous. When lifting metal sheets (whether single or stacked), specialized hooks, pliers (such as C-hooks, vacuum suction cups), or sturdy steel wire ropes/nylon slings must be used to pass through the reserved lifting holes. No matter how tightly the steel belt is tied, it is only a "waistband", not a "sling".

Key details of rust prevention and protection:

Rust prevention: The steel strip itself will rust. If bundling materials such as stainless steel, galvanized sheet, or aluminum sheet that require a beautiful surface, long-term bundling may cause rust stains on the steel strip and contaminate the surface of the sheet. At this point, either use stainless steel strapping or place rust proof paper or plastic film between the steel strip and the plate to separate them.

Corner protectors: As mentioned earlier, when bundling flat pallets, the edges of the four corners of the board must be protected with thick corner protectors to protect the steel strip. Otherwise, if the transportation bumps a few times, the edge of the board will cut the steel strip like a knife.

Button position: It is best to place the button (seal) on the side or back of the board, not on the prominent front, otherwise there may be pressure marks or scratches on the surface of the board after unloading.

English

English

中文简体

中文简体