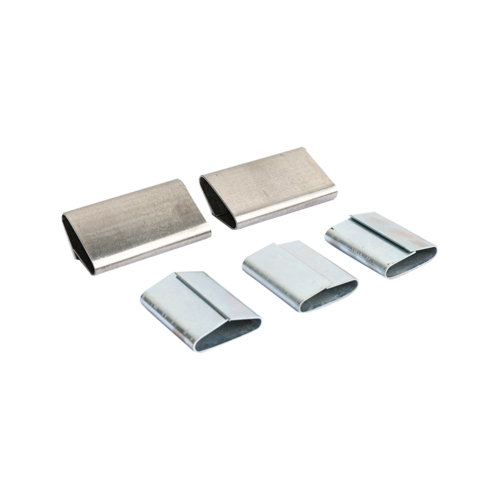

It is important to ensure that the steel straps are straight and not twisted when using steel strapping buckles. The flatness of the steel strip directly affects the binding effect and stability. If the steel strip is twisted or uneven during the locking process, it may result in uneven distribution of binding force, affecting the fixing effect and even causing the buckle to not fully engage or loosen. When binding objects, the twisted steel strip will increase additional stress concentration, causing the steel strip to bear excessive local loads, which not only reduces the stability of the fixed object, but may also cause damage or deformation of the steel strip.

The twisting or bending of the steel strip can also affect the tightness of the locking mechanism. If the steel strip is not fully straightened, the buckle may not be able to bite accurately, resulting in weak binding and increasing the risk of item movement during transportation or storage. Therefore, when performing bundling operations, it is necessary to ensure that the steel strip is straightened and flat, which can ensure a tighter fit of the buckle, thereby providing stronger fixing force and higher safety.

The correct use of steel strapping buckles requires the steel strip to be kept straight and free from distortion, in order to ensure maximum binding effect and avoid looseness or damage caused by unevenness. The correct operation method is to completely straighten the steel strip and eliminate any bending and twisting, and then use bundling tools to tightly fix the steel strip, which can improve the stability and safety of bundling.

English

English

中文简体

中文简体